2017 Serco Industrial HVLS Fan

Safer. Stronger. More Efficient.

The BEST HVLS Fan on the market continues to improve.

http://www.architectmagazine.com/technology/hot-summer-days-bring-them-on-says-plant-manager

WE MOVE MASSIVE AMOUNTS OF AIR. PERIOD.

Our HVLS airflow pattern ensures air movement reaches all corners of your facility, maintaining consistent conditions throughout your building and eliminating condensation issues that may affect worker comfort, floor traction or product integrity.

Too big? Click here to check out our other industrial fans.

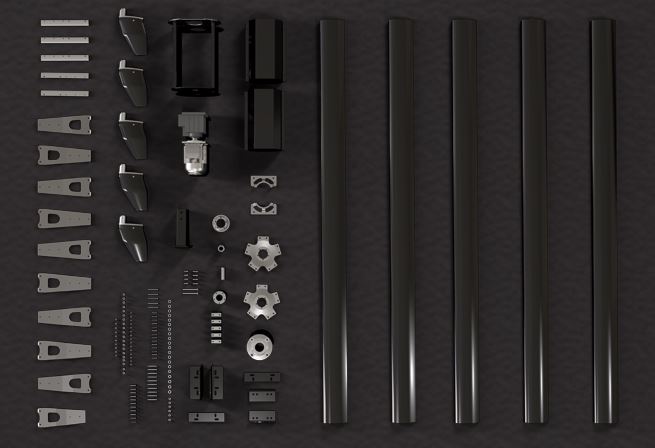

This is more than just a Big A$$ Fan, we've gone beyond the hype to deliver real results.The Serco Industrial Series Fan is advancing HVLS technology through advanced controls, improved airflow, and energy effeciency. The Serco ATEC features an advanced blade profile which means greater product life, while the five (5) blade design achieves maximum airflow efficiency. Inspiration for the blade and winglet design come from the Apache Attack Helicopter. Our black, anodized blades look great and deliver the airflow you expect.

- Keep employees cool and comfortable. The 2-3 mph breeze delivers the equivalent of a 7-11 degree reduction in the perceived temperature.

- Reduce energy consumption. Working with the HVAC system, Serco fans help regulate temperature from ceiling to floor, which can allow a facility to raise its thermostat setting 3 - 5 degrees. This creates a potential energy savings of up to 4% per degree change.

- Protect product integrity. Air circulation helps keep food and produce dry and fresh, reducing potential for decay or spoilage - Air circulation reduces stagnant air, hot and cold spots and condensation - Serco fans are also designed to operate in reverse, which helps de-stratify air in cool season operation.

- Improve working conditions. Floor condensation is minimized, keeping floors drier and safer for foot and motorized traffic - Improved indoor air quality through the dispersing of fumes - Fans can be operated from a centralized location using Serco iFAN network controls (sold separately), allowing a facility to easily monitor fan activity and performance.

- Contribute to LEED certification in various categories. Energy efficiency and atmosphere. Indoor environmental air quality. Innovation and design.

Not just for cooling. Run your fan in reverse during the winter.

HOW HVLS FANS WORK

The Serco ATEC’s airfoil style blade design produces a massive, cylindrical column of air that flows down to the floor and outward in all directions, creating a horizontal floor jet that consistently circulates air in large spaces. This “horizontal floor jet” pushes air a greater distance before it is pulled back vertically toward the blades. The greater the down flow, the greater the air circulation and resulting benefits. In the colder months, fans can be run in reverse to circulate the hot air trapped at ceiling level known as “destratification."

HVLS FAN SIZES RANGE FROM 8' DIAMETER UP TO 24' DIAMETER.

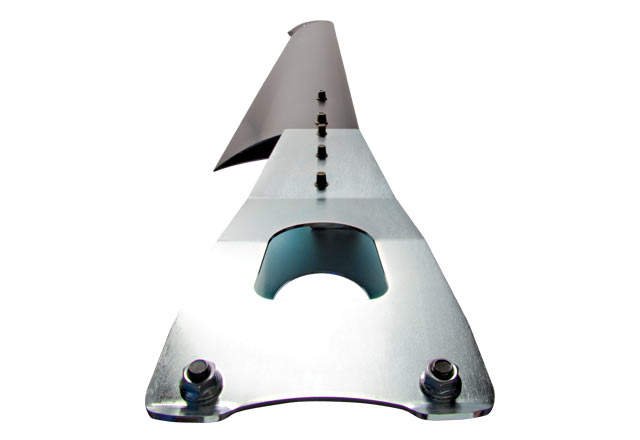

Designed to be the Safest and Most Efficient HVLS Fan

“The guys in my warehouse swear by them. That’s why I put additional fans along my packaging line and adjacent to the docks.”

Side-by-side comparison. Our 5-Blade fan moves more air than the competition. Shown above in Stealth-Black Powder Coat.

HVLS Fans Provide Numerous Benefits to Your Facility

- Provides a more comfortable, uniform temperature for employees

- Changes the perceived temperature of an employee by 7-11 degrees

- Slow movement is quiet and non-disruptive to employees and the work environment

- Air movement keeps facility floors dry – improving overall safety

- Condensation is minimized – protecting the facility and product from moisture and mold

- Helps circulate and minimize the effect of forklift exhaust and stagnant or musty air

- Equalizes temperature to a +/- 1 to 2 degree difference from floor to ceiling

- Improves environmental conditions at the top of storage racks

- Reduces the load on air handlers and improves cycle times

- Reduces extreme heat at mezzanine levels in warehouse

- Digital touchscreen control can be password protected, so you're in charge

Safety is our main priority, even with fans. Our units feature multiple safety improvements over the competition.

The Details Matter.

How do you make your fan even MORE efficient? It starts with having the best motor & Variable Frequency Drive system on the market.

We don't mess around with flimsy fan blades that droop when powered off, or lift excessively at full speed. During the "Step-Test" our blade can handle the weight of a person on it. Oh, and did we mention that the blade profile is fully optimized to produce a downforce column of air?

Customize YOUR fan:

- Custom Powder Coated Blades

- Custom Logo on Hub Cover

- Custom Color Winglets

- Corrosion Resistant Package

- Multi-Fan Control

- Indoor/Outdoor Temperature Control

- BACNET Interface Card

- Modbus Interface

- NEMA 4X Enclosure

- iFan System

- Tablet Control

- Exhaust Fan Integration

- External Wind Sensor

- Multiple Building Control

- Fire Control System Interface

“This fan moves a ton of air. More air than I would’ve expected. It just gets so hot and humid during the summer, that we could never go back.”

Does your facility have Sustainability & LEED Initiatives?

Energy and Atmosphere

- Prereq 2 – Minimum Energy Performance [Required]

- Credit 1 – Optimize Energy Performance [1-19 points]

Indoor Environmental Quality

- Prerequisite 1 – Minimum Indoor Air Quality Performance (Required) &

- Credit 2 – Increased Ventilation [1 point]

- Credit 7.1 – Thermal Comfort—Design [1 point]

Innovation in Design

- Credit 1 – Innovation in Design [1-5 points]